HMI Technology Helps Improve the Stretch Wrapping Process

This is the first of a five-part blog series that discusses the advantages of HMI-controlled stretch wrapping solutions.

Take a step back and observe everyday life. What’s a common thread woven through just about everything we do? Technology … and smart technology at that.

It’s become a universally-accepted standard in people’s lives, from the way you travel from one point to another, to managing your finances, to the entertainment you watch, to the way you communicate with family and friends – just to name a few examples, smart technology has permeated just about every aspect of our lives.

This same level of functionality is now seen in stretch wrapping solutions as well – and that’s a good thing.

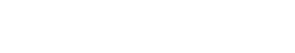

Smart technology is making stretch wrapping machinery more efficient and easier to operate. It’s not something to be fearful of. Yet, there seems to be a lingering perception within the packaging industry that stretch wrapping machinery outfitted with touchscreen HMI controls is something to be leery about. In reality, nothing could be further from the truth.

Part of this misconception may stem from a reluctance to embrace new technologies in packaging equipment. An HMI interface may be intimating to someone who’s never seen one on a stretch wrapper before. They may be more comfortable with a familiar look of an older unit and the way that operates. They may also see HMI controls as expensive; an unnecessary additional cost that’s really not justified, or just not as reliable as mechanically-controlled models.

Take a closer look at the advantages HMI controls can bring to your next stretch wrapping solution. You might just be surprised.

Check back on February11, for Part 2 in the Series.

For notification of our latest blog post follow Orion Packaging on Linked In.